Truck ECM Repair

Module Repair Lab restores and services engine control modules (ECM/ECU) for Class 7–8 semi trucks. We address no-start, no-communication, derate, unstable power regulation, and heat/moisture-related board faults — with 1–3 business day turnaround, warranty-backed work, and nationwide mail-in or California drop-off.

Supported platforms include Cummins, Detroit Diesel (DD13/DD15/DD16 + CPC4), and PACCAR (MX-13) across Freightliner, Kenworth, Peterbilt, International/Navistar, Mack, and Volvo Trucks. Select a service below to confirm compatibility, turnaround, and pricing for your ECM.

Popular Semi-Truck ECM & CPC4 Repairs

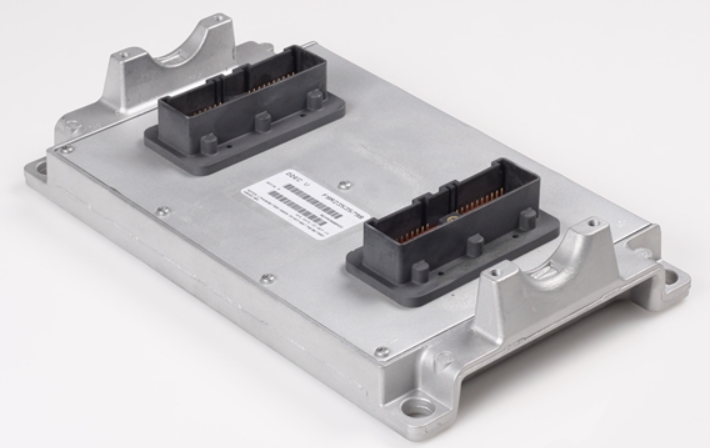

Semi-Truck ECM Repair & Replacement | Heavy-Duty Engine Control Modules

Our focus is semi-truck ECM/ECU repair, cloning, and bench validation for Class 7–8 on-highway platforms. Typical symptoms include no-start, no communication (no-comms), CAN bus faults, derate/limp mode, random shut-downs under load, and persistent hard fault codes. We take a board-level approach to stabilize power regulation, ground integrity, communication drivers, and heat-stressed interconnects — then we bench test before return shipment. When the platform supports it, we perform data-preserving cloning to maintain VIN, calibration, injector coding, and learned parameters to reduce on-vehicle programming time.

Common ECM Problems

- No-start or intermittent start after jump-start or battery change

- No communication with the ECM (CAN faults, “No ECM” messages)

- Derate or unstable idle with no clear external cause

- Random shutdowns or loss of power under load

- Repeated hard fault codes despite sensor/harness checks

- Heat discoloration, burnt odor, moisture or corrosion at the connector

Why Heavy-Duty ECMs Fail (Root Causes)

On-highway trucks face heat, vibration, and electrical stress. Low-voltage cranking, weak or overcharging alternators, and jump-start events can damage voltage regulators and communication drivers. Moisture intrusion and connector corrosion create intermittent faults that mimic sensor issues; thermal cycling fatigues solder joints and flex interconnects. We target these root causes so the controller returns stable and repeat failures are less likely.

- Power integrity events: low-voltage cranks, alternator over-voltage, jump-starts

- Thermal cycling & vibration: fatigues solder joints and ribbon interconnects

- Moisture & contamination: corrosion at pins and inside housings

Repair

We diagnose the failure mode, restore power/ground paths, replace stressed regulators and comms drivers, repair traces and micro-solder joints, and validate communications & key I/O on the bench. Repair preserves your original hardware and often costs less than replacement.

Replace

Severe corrosion, fire/heat damage, or no-power logic boards can make replacement the safe choice. If feasible, we clone data to a donor ECM to preserve VIN and calibration. We only recommend replacement when it’s the reliable path forward for uptime.

Cloning (When Supported)

Data-preserving cloning can carry over VIN, engine calibration, injector trim codes, idle and governor parameters, and certain PTO-related settings depending on the ECM family (e.g., Cummins ISX/X15, Detroit DD15, PACCAR MX-13). Not every platform permits full cloning; when it does, it minimizes programming time and speeds return to service.

Simple Checks Before Sending

- Load-test batteries and verify alternator output (under/over-voltage causes repeat failures)

- Inspect ECM connectors for water intrusion, green corrosion, and pin push-out

- Note if symptoms started right after electrical work or a jump-start

Platforms We See Often

Cummins: ISB, ISC, ISX, X15 (Freightliner, Kenworth, Peterbilt, International) — non-start after jump, CAN faults, regulator failures.

Detroit Diesel: DD13, DD15, DD16 — intermittent no-comms, power rail instability; CPC4 units with boot failures and CAN driver faults.

PACCAR: MX-13 in Kenworth & Peterbilt — comms line repair, power/ground restoration, selective cloning depending on the donor & software.

Cost of ECM Repair

- Repair pricing varies by ECM family and failure mode; we favor repair over replacement when reliable

- Cloning may require sourcing an appropriate donor; we confirm options, risks, and timelines before proceeding

- Transparent scope — no unnecessary services, clear communication up front

Shipping & Packaging

- Protect connectors; use anti-static or clean bubble wrap and sturdy padding

- Double-box for long-haul shipments; include your order number

- Do not include unrelated parts in the box

Warranty & Post-Install Support

Repairs include a 3-month warranty on the work performed. After installation, if codes or symptoms persist, contact us with details so we can help differentiate vehicle-side wiring and power issues from controller behavior, and advise next steps for a reliable fix.

Why Choose Module Repair Lab

Fleets, diesel shops, and owner-operators choose us for precision electronics work, predictable timelines, and clear communication. We work on semi-truck ECMs every day, maintain focused harnesses & test setups, and back our work with support after installation — fewer surprises and faster return to service.

How It Works

- Select your service: Choose Cummins, Detroit (CPC4 supported), PACCAR MX-13, Volvo/Mack, or CPC4-only.

- Ship your ECM: Follow the packaging tips; include VIN, engine family, and a brief symptom description.

- Diagnose & repair: We perform board-level repair and bench validation; cloning if supported.

- Return & install: We provide any platform-specific relearn/initialization notes if needed.

Restore Engine Uptime

Whether it’s a Cummins ISX/X15 no-start, a Detroit DD15 no-comms or CPC4 boot failure, or a PACCAR MX-13 comms driver issue, we’ll help chart the most reliable path to a working controller with minimal downtime.

Freightliner Cascadia CPC4 Repair: No Throttle Issue→ Bench-Validated

Frequently Asked Questions (FAQ)

Do you work on CPC4?

Yes — we service Freightliner / Detroit CPC4 power, communication, regulator, and boot failure issues. Many Detroit DD13/DD15/DD16 no-start or no-comms complaints involve both ECM and CPC4; we can evaluate the controller you send and advise next steps.

Will my ECM return plug-and-play?

Often yes when we clone or preserve original data. Some platforms still need on-vehicle initialization or relearn steps; we’ll note this on your work order if applicable.

Turnaround time?

Typical turnaround is 1–3 business days from receipt. Rush options may be available — contact us to confirm current capacity before shipping.

Do you tune or modify emissions settings?

No — we don’t offer tuning or emissions deletes. Our scope is diagnostics, board-level ECM repair, and data-preserving cloning where supported.

What should I include when shipping the ECM?

Include contact info, VIN, year/make/model, engine family, and a short symptom description. Protect connectors and pack with sufficient padding. Label the box with your order number.

What if the ECM isn’t repairable?

We’ll share findings and options (return as-is, donor replacement, or cloning if supported). No surprise charges — we confirm before proceeding.