Cummins N14 Celect ECM Repair – Fast, Reliable Service for Your N14 Engine

When a Cummins N14 Celect equipped truck starts losing power, refuses to start, or stops

communicating with your diagnostic tool, the engine control module (ECM) is often the part

responsible. Replacement Celect ECMs are difficult to source, expensive, and may require

programming or calibration after installation. Our Cummins N14 Celect ECM repair

service gives drivers and fleets a cost-effective, reliable way to get their trucks back on the

road without the expense of replacing the entire module.

Module Repair Lab specializes in repairing the original ECM you send in. Because

we repair your own Celect ECM, your existing engine settings and programming are typically

preserved. This avoids reprogramming charges, dealership scheduling delays, and fitment problems.

Whether you operate a single truck or manage an entire fleet, our goal is to keep your N14 engine

running dependably with fast turnaround and clear communication throughout the process.

Common Symptoms of a Failing N14 Celect ECM

The Celect system controls crucial N14 engine functions such as fuel delivery, timing, idle speed,

and emissions-related logic. When the ECM begins to fail internally, the engine will usually show

one or more of the following symptoms:

-

Crank but no start: Engine cranks normally but will not fire, even after

checking sensors and fuel supply.

-

No communication: Your scan tool cannot connect to the Celect ECM despite

power and ground checks confirming voltage at the harness.

-

Unexpected engine shutdown: The engine may stall randomly during operation, then

restart after sitting or cooling down.

-

Erratic idle or surging: Idle speed changes unpredictably, or the engine hunts

under light throttle.

-

Incorrect or conflicting fault codes: Multiple codes appear, disappear, or

return even after replacing sensors or verifying wiring.

-

Loss of power: The truck may feel weak, hesitate on acceleration, or respond

poorly to throttle input.

-

“Dead” ECM: No power-up, no response, and no datalink activity from the

module.

These issues are commonly reported on N14 Celect engines and, once truck-side problems are ruled

out, usually indicate internal ECM trouble.

Why Celect ECMs Fail

N14 Celect ECMs operate in a demanding environment. Over years of service, several real-world

factors repeatedly contribute to internal failures:

-

Heat stress: Repeated heating and cooling cycles cause expansion and

contraction of internal components. Over time, this thermal cycling can weaken solder joints

and stress critical components.

-

Vibration exposure: Heavy-duty trucks create constant vibration that can

fatigue solder joints and connectors inside the ECM, especially on older modules.

-

Electrical fluctuations: Low voltage, weak batteries, poor grounds, or

jump-starting events can overload internal power circuitry.

-

Age-related component wear: Many N14 Celect trucks have hundreds of thousands

of miles on their original ECMs, making component failure more likely.

-

Moisture or contamination: Water intrusion or contaminants entering through

connectors can corrode internal traces and connections.

These issues can cause intermittent symptoms at first, then worsen until the truck becomes

unreliable or stops running altogether.

Our N14 Celect ECM Repair Process

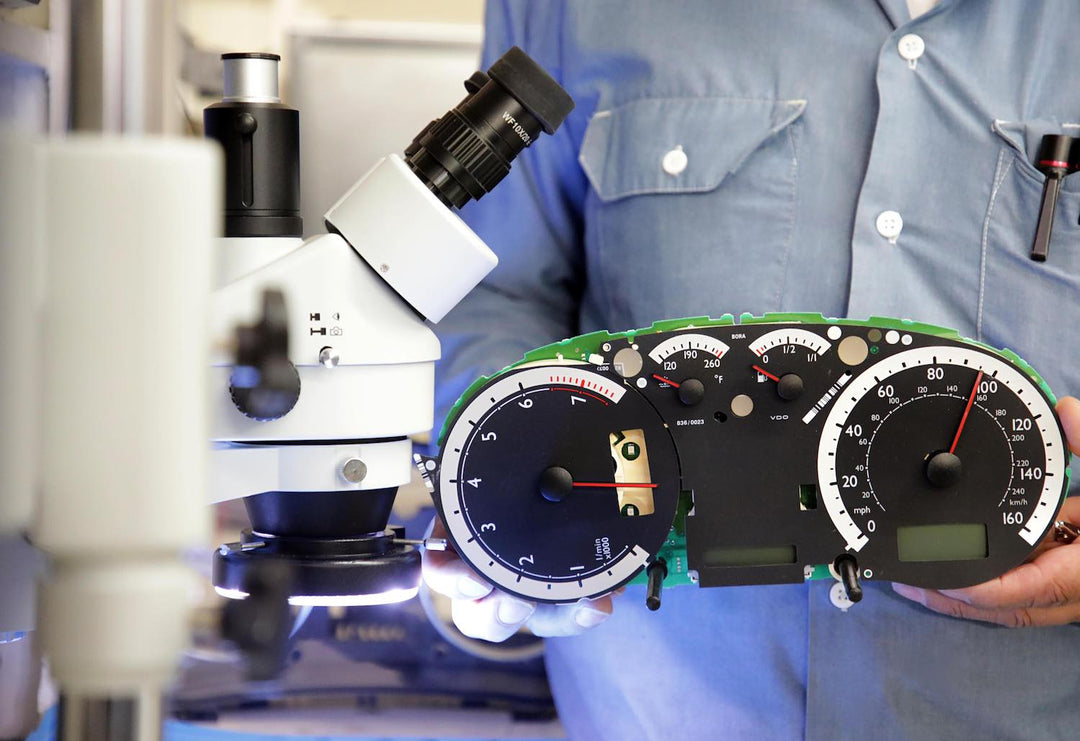

We follow a structured, detail-oriented workflow built around the specific needs of Celect

controllers:

-

Complete inspection: Once your ECM arrives, we open the unit and examine the

board for signs of heat damage, aging components, corrosion, or cracked solder joints.

-

Power & ground evaluation: We verify that the ECM’s internal power supplies

operate correctly, as many Celect failures trace back to regulation issues.

-

Signal path testing: We evaluate communication circuits, drivers, and logic

areas responsible for datalink and fuel control.

-

Component replacement: Any failing or out-of-range components identified during

testing are replaced with appropriate equivalents.

-

Solder rework: Aging joints and stressed areas are reworked to restore

reliability.

-

Cleaning & preservation: The board is cleaned to remove residue and reduce

the risk of future corrosion.

-

Bench testing: The ECM is powered and tested to validate that it responds

predictably before we return it.

Supported Applications

This N14 Celect ECM repair service supports most Celect-equipped:

- Freightliner

- Kenworth

- Peterbilt

- International

- Western Star

If you’re not sure whether your ECM is covered, send a photo of the ECM label and we’ll confirm.

Mail-In Repair Service – How It Works

-

Place your order for the Celect ECM repair service.

-

Remove the ECM from the truck (disconnect batteries first).

-

Ship the ECM to us securely, including your contact info and symptom details.

-

We diagnose and repair your module with typical turnaround of 1–3 days.

-

We return the repaired ECM ready for reinstallation.

Actual turnaround may vary depending on workload and ECM condition.

Warranty & Service Information

-

Service Type: Board-level repair of your original Celect ECM.

-

Programming: Your calibration is usually preserved.

-

Turnaround: About 1–3 business days once received.

-

Warranty: Terms listed on this product page apply.

Frequently Asked Questions

Does this repair guarantee my N14 will start?

Not always — wiring and truck-side issues must be ruled out. But when the ECM is the problem, repair typically resolves the issue.

Will I need to reprogram after repair?

No. Because we repair your original ECM, your calibration usually stays intact.

Can you fix water-damaged ECMs?

Light to moderate corrosion may be repairable. Severe damage may not be reliable enough for repair.

What if my ECM is not repairable?

We will contact you with findings before proceeding.