CPC4 ECM Repair for Freightliner Cascadia & Western Star Trucks

Module Repair Lab provides professional CPC4 ECM repair services for Freightliner Cascadia and Western Star trucks equipped with Detroit Diesel engines. When a truck has persistent no-start, no-communication, derate, or intermittent electrical problems that have been traced to the CPC4, we perform structured, board-level diagnostics and repair to restore reliable operation.

This is a repair service for your existing CPC4 module. You ship your CPC4 to us, we test it on the bench, carry out repairs when possible, and ship the same module back to you. Because your original controller is retained, your existing programming is typically preserved.

Important: The symptoms described on this page can also be caused by wiring, battery, power/ground, or other modules on the vehicle. A technician should perform basic diagnostics on the truck side before condemning the CPC4.

The Role of the CPC4 on Detroit Diesel–Equipped Trucks

The CPC4 (Common Powertrain Controller) is a central part of the powertrain control and communication system. It communicates over the J1939 CAN network with the engine ECM, transmission controller, aftertreatment system, ABS, and other vehicle modules. When operating correctly, the CPC4 helps coordinate powertrain functions, manage certain power feeds, and support consistent communication across the network.

Because of this central role, a failing CPC4 can produce issues that show up in several different systems at the same time. That is why confirming CPC4 health with proper testing is so important.

Common CPC4-Related Symptoms Seen in the Field

Technicians and fleets often see the following types of issues when a CPC4 is involved, especially after wiring and power checks have been completed:

- No-start or intermittent start: Engine cranks but control modules do not fully communicate or remain online.

- No communication: Scan tools are unable to establish communication over the vehicle datalink, even though power and grounds appear correct.

- Derate or limp mode: Power or speed derate conditions associated with CPC-related or J1939 communication faults.

- Multiple network fault codes: Codes indicating communication problems between the CPC4, engine ECM, transmission, ABS, or other modules.

- Intermittent voltage issues: Circuits that are powered or controlled through the CPC4 may lose power, drop out under load, or behave inconsistently.

- Unpredictable dash or warning light behavior: Powertrain-related warning lamps or messages that appear and clear intermittently without a clear mechanical cause.

These symptoms alone do not confirm a CPC4 failure, but they are commonly associated with modules that later test faulty on the bench.

Why CPC4 Modules Commonly Fail

CPC4 modules operate in a demanding environment, and several real-world factors are frequently linked with internal failures. These factors are consistent with what technicians, fleets, and electronics specialists see when testing defective modules:

- Thermal cycling: During normal operation, the CPC4 repeatedly heats up and cools down. This ongoing expansion and contraction can fatigue solder joints over time, including joints under high-density and BGA (Ball Grid Array) components, leading to intermittent or unstable connections.

- Vibration and mechanical stress: Heavy-duty trucks subject the CPC4 to continuous vibration. This mechanical stress can contribute to solder fatigue, cracked joints, and strained connector pins, especially if the module or harness is not well supported.

- Voltage irregularities: Low system voltage, weak or failing batteries, poor grounds, and jump-start events can stress internal power regulation and driver circuits, contributing to unstable operation or no-start conditions.

- Moisture and contamination: Moisture entering connectors or, in some cases, the housing can promote corrosion on pins and circuit traces. Contaminants and residues may also contribute to leakage paths and intermittent behavior if left unaddressed.

- Connector and harness strain: Harness tension, movement, or improper support can place additional stress on connector solder joints and pads inside the module, increasing the likelihood of intermittent faults.

These factors do not guarantee a CPC4 will fail, but they explain why modules in similar service often develop comparable internal issues over time.

Our CPC4 ECM Repair Process

Each CPC4 that arrives at Module Repair Lab goes through a structured, repeatable repair process designed around what is actually seen in the field. Where applicable, this process includes careful attention to BGA-mounted devices and other high-density components.

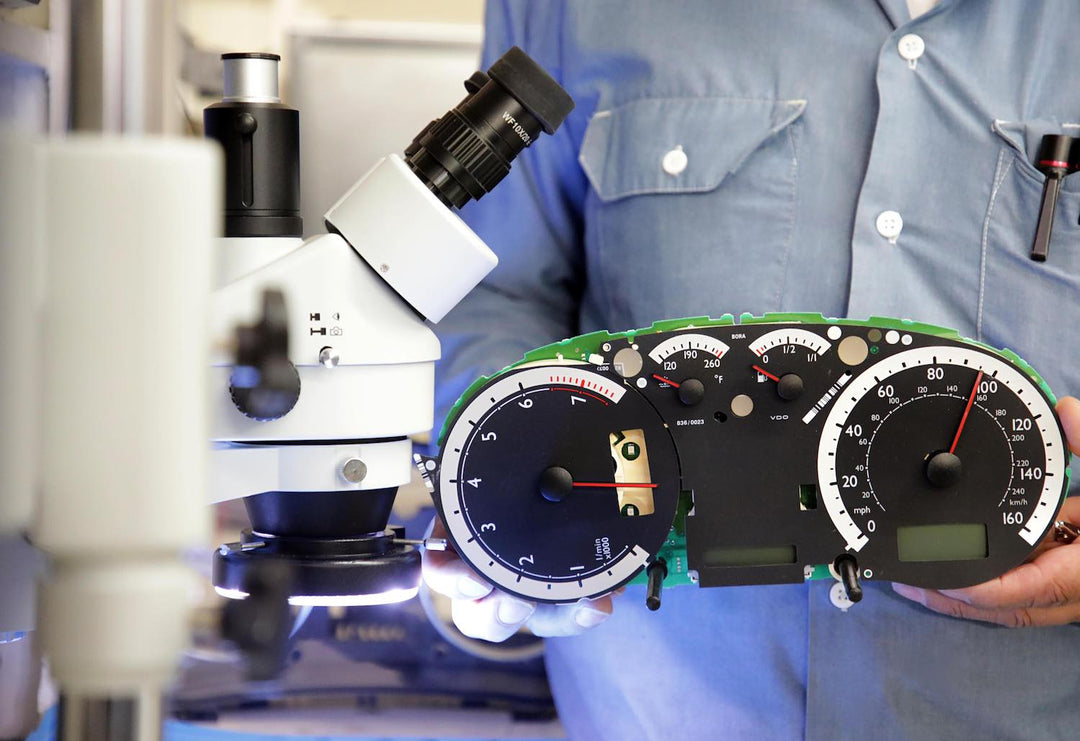

- Board inspection: We open the module and inspect the circuit board under magnification. We look for heat discoloration, corrosion, contamination, cracked solder joints, stressed connector areas, and prior repair attempts. Particular attention is given to common stress points and high-density components, including BGA packages.

- Power and ground evaluation: On the bench, we check key power inputs, internal power rails, and grounds. Problems in these areas are often associated with no-start, no-communication, and unstable operation.

- Communication circuit testing: We evaluate circuits involved in communication, including those related to the J1939 CAN network, to identify issues that may cause datalink loss, intermittent communication, or repeated network-related fault codes.

- Component-level repair: When diagnostics indicate that specific electronic components (such as power regulators, drivers, or communication-related devices) are damaged or not performing within normal limits, we replace them with appropriate, function-matching parts.

- Solder rework and BGA service: In areas where solder fatigue or mechanical stress is identified, we perform targeted solder rework. When evidence points specifically to BGA-related connection issues, we may carry out controlled BGA reflow. In more severe cases, where joint integrity cannot be restored through standard rework, full BGA reballing may be performed using established industry practices.

- Cleaning and preservation: After repair work, we clean the board to remove residues and contamination. Clean circuitry helps reduce the risk of corrosion-related problems and improves long-term reliability.

- Bench testing: Once repairs are complete, we power the CPC4 in a controlled test environment and verify that it powers consistently and responds as expected on the bench before returning it.

If we find that the CPC4 is severely damaged—for example, from extreme corrosion, fire, or major physical damage that compromises pads and traces—we will contact you with our findings before moving forward.

How the Mail-In CPC4 Repair Service Works

- Place your order: Complete checkout for this CPC4 ECM repair service. You will receive an order confirmation by email with your details.

- Remove the CPC4 from the truck: Follow standard safety procedures. Disconnect the batteries before unplugging the module. Carefully remove the CPC4, protecting connectors from dirt and moisture.

- Package and ship: Wrap the CPC4 in protective material and ship it in a sturdy box. Include your contact information, truck year and model, engine type, and a brief description of the symptoms and fault codes observed.

- Testing and repair: After the CPC4 arrives, we perform diagnostics and carry out board-level repairs where possible. Our typical in-house turnaround goal is 1–3 business days, not including transit time.

- Return shipping: Once testing is complete, we ship your CPC4 back to you. In many cases, customers are able to reinstall the repaired module and continue using their existing programming.

Actual turnaround may vary depending on workload, shipping times, and the condition of the module.

Service Details & Warranty

- Service type: Board-level repair of your original CPC4 module

- Programming: Because your original controller is repaired, your existing programming is generally preserved

- Turnaround goal: Approximately 1–3 business days in-house after your CPC4 arrives

- Warranty: Warranty coverage and duration for this repair are described on this product page and in your order confirmation. Please refer to those terms for the most current details.

Vehicle Compatibility

This CPC4 ECM repair service is intended for CPC4 modules used on:

- Freightliner Cascadia trucks equipped with Detroit Diesel engines that use CPC4 controllers

- Western Star trucks equipped with Detroit Diesel engines that use CPC4 controllers

If you are unsure whether your specific CPC4 part number is covered, please contact us with clear photos of the label and we can confirm whether this service is appropriate for your module.

Compatible CPC4 Part Numbers

The following CPC4 module part numbers are commonly used on Freightliner Cascadia and Western Star trucks equipped with Detroit Diesel engines and are supported by this repair service. If your module’s label matches any of the part numbers below, it is considered compatible for testing and repair:

- A0034461002 / 001

- A0034461002 / 002

- A0034461002 / 003

- A0034461002 / 004

- A0034461002 / 005

- A0034461102 / 002

- A0034461102 / 003

- A0034461102 / 004

- A0034461102 / 005

- A0034461202 / 001

- A0034461302 / 001

- A0064463402 / 001

If your CPC4 has a similar part number not shown here, feel free to contact us with a clear photo of the label. Many CPC4 variants share similar internal design and may still be eligible for repair.

Nationwide Mail-In & California Options

Module Repair Lab serves customers across the United States through our mail-in program. For customers located in California, local options may be available depending on current scheduling and logistics. Contact us for current information if you are interested in a local drop-off arrangement.

Frequently Asked Questions

Do these symptoms always mean the CPC4 is bad?

No. Similar symptoms can result from wiring problems, low voltage, poor grounds, or faults in other modules. We recommend that you or your repair facility perform truck-side diagnostics before sending the CPC4 in for repair.

Will my CPC4 need to be programmed after repair?

In many cases, customers can reinstall the repaired CPC4 and continue using their existing programming, because the original controller is repaired rather than replaced. However, behavior can vary depending on vehicle history and configuration.

Are water- or fire-damaged CPC4 modules repairable?

Some modules with light to moderate corrosion may be repairable. Severe water, fire, or impact damage can leave the CPC4 in a condition that is not suitable for reliable repair. If we find that your module is not a good candidate, we will contact you with our findings.

What happens if my CPC4 cannot be repaired?

If testing shows that the CPC4 is not a strong candidate for reliable repair, we will reach out to you to explain what we found and discuss your options before proceeding.

How do I get started?

Place an order for this CPC4 ECM repair service, remove the module from your truck, and ship it to Module Repair Lab with your contact information and a description of the issues. We will handle the bench testing and, when possible, board-level repair, then return the module to you.

Please ship your module to the following address:

Module Repair Lab

8698 Elk Grove Blvd Ste 1, Elk Grove, CA 95624

Make sure to include your contact information and order number inside the package to help us process your repair quickly.

We recommend using a trackable and insured shipping method to ensure safe delivery. Once your repair is complete, we will ship it back to the return address you provide.

If you have any questions, feel free to contact us.

How it Works

We offer a cost-effective solution to pricey dealership part replacements, saving you a significant amount of money. Our approach goes beyond simply repairing the faulty part – we address the underlying issue and use top-quality upgraded parts to ensure a long-lasting fix. We stand behind our service with a 100% satisfaction guarantee or your money back.

- To get started, carefully remove the part from your vehicle. If you’re unsure how to do this, you can take it to your local body shop for assistance.

- Once the part is removed, pack it securely in a suitable box to prevent any damage during transit.

- Don’t forget to print out your order confirmation page and include it in the package, along with your name, return address, and phone number

FAQs

8698 Elk Grove Blvd #1, Elk Grove, CA 95624

info@modulerepairlab.com

Turnaround time is fast—typically 2 to 3 business days once we receive your module.

You can pay on the website with PayPal or a credit card or you can send the module in with your information and we will contact you for a credit card after the repairs have been performed.

Yes, warranty depends on the module being repaired.